Vision ReDefined

Robust

Our AI-powered products that are not only technologically advanced but also built to endure real-world challenges.

Intelligent

Intelligence lies at the heart of everything we do. Our products harness the power of AI, enabling them to learn, adapt, and evolve.

Revolutionary

Our revolutionary approach to technology not only brings transformative changes in the automotive industry but also paves the way for new possibilities.

.png)

Our Partners

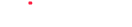

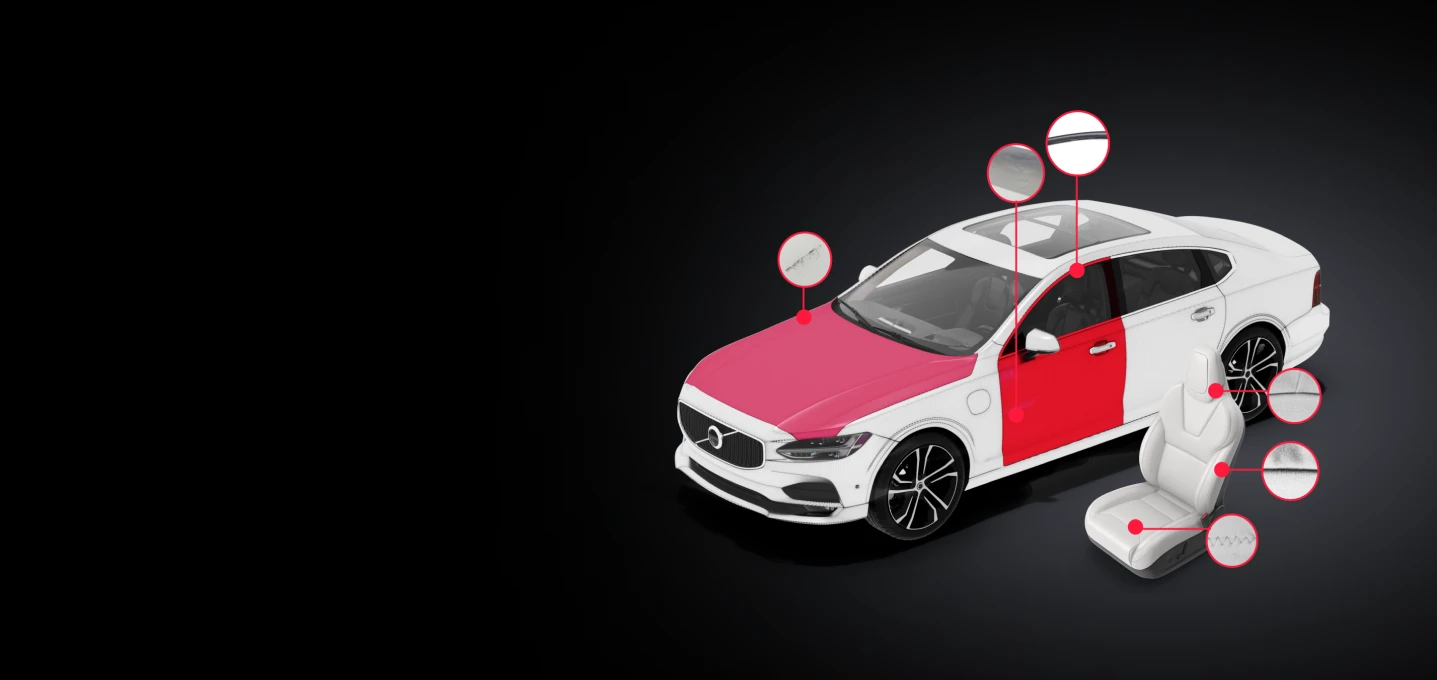

Inspection AI

Inspection AI helps Automobile, Part manufacturing & manufacturing companies to automate the manual quality inspection process using AI and achieve 6Sigma

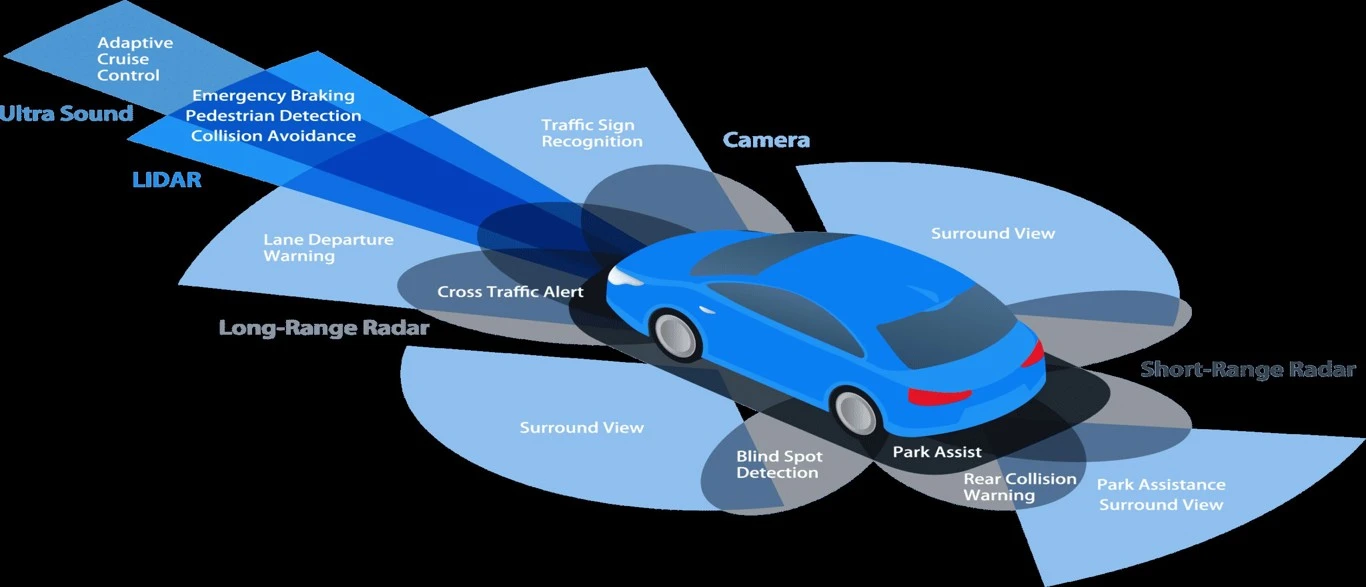

Vision Drive

Vision Drive is designed to excel in harsh road conditions, such as those encountered in regions like Pakistan. Our Uncertainty Estimation Algorithms play a vital role in assisting global Automotive OEMs with thorough testing of their ADAS in the challenging driving environments of Pakistan.

.webp)

IntelliSentry

Safeguard car with confidence and stay one step ahead of potential threats with IntelliSentry's intelligent surveillance technology. Harnessing the power of AI and real-time monitoring, it provides proactive threat detection.

PDRIVE20K

Welcome to Pakistan's inaugural publicly available autonomous driving dataset, featuring an extensive range of diverse scenes and the multifaceted road environments and conditions that define the Pakistani landscape. This dataset is a valuable resource for researchers and autonomous driving companies, offering a comprehensive view of the challenges and opportunities unique to Pakistan's roads.

We are Always Looking For impact makers

We always have multiple positions open for wide range of impact creators.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)