Inspection AI Core Features

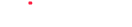

Quality Inspection

Realtime inspection of each part, if it fails or passes the quality inspection.

Cause Analysis

Help in identifying the root cause of the abnormal increase in defects.

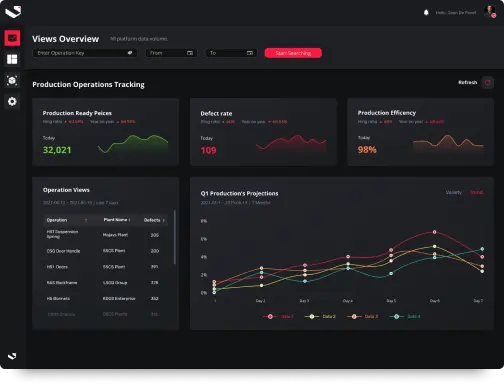

Inspector Dashboard

Realtime insights of the day to day Quality inspection and defects for the Quality Inspection Team

.svg)

Dashboards

Bird eye view of all the defects and revenue losses to better understand the quality issues

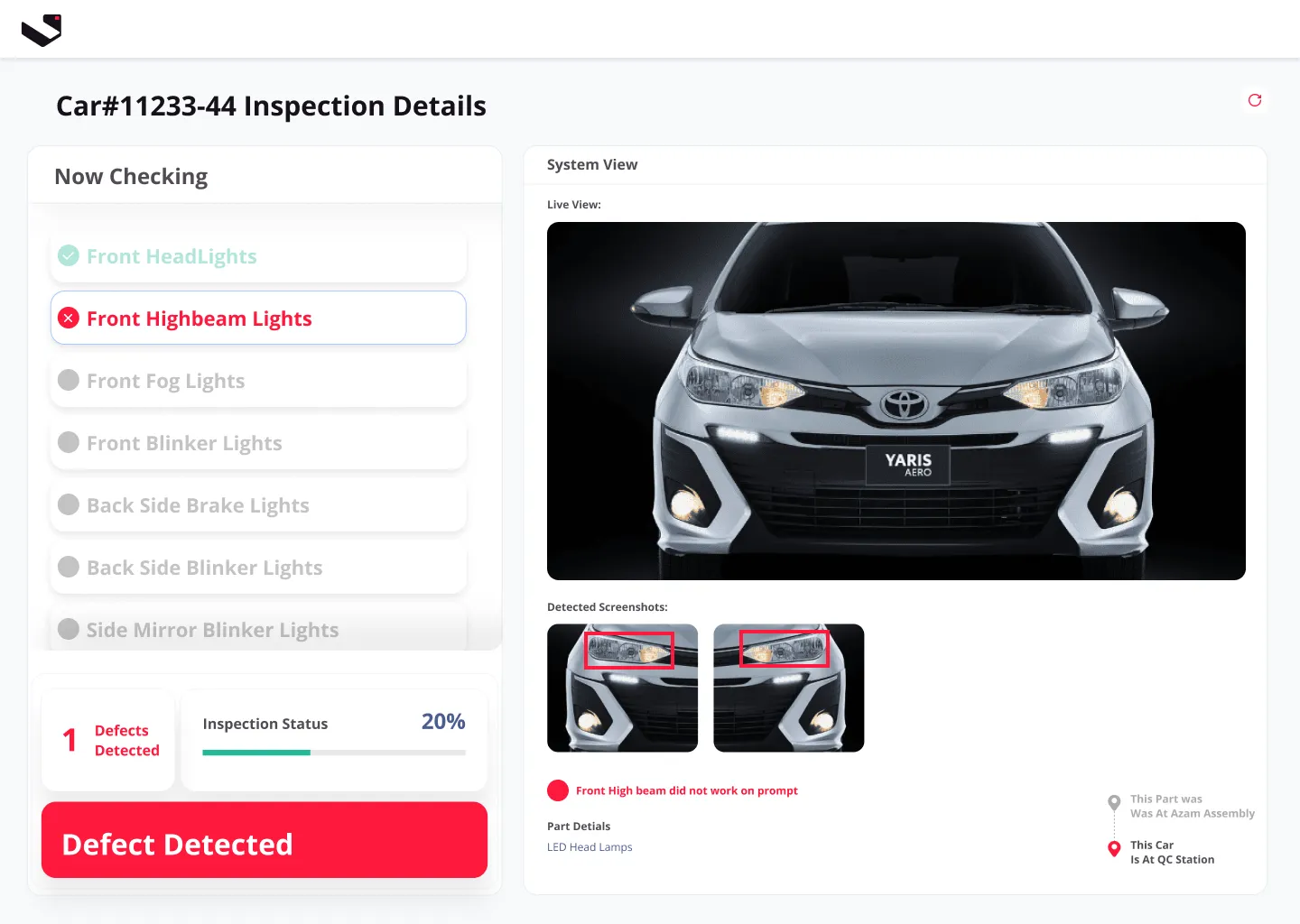

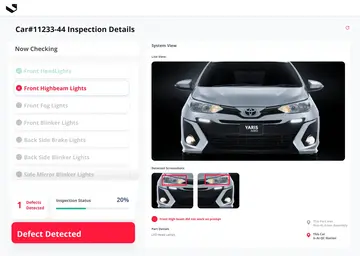

Products Images

Analyze the images of defective products.

Improvement

Continuously improve the AI models so they work well for inspection

Camera &

Hardware

Our Camera and Hardware are installed at the end of inspection line and are low maintenance. Our System consists of a Hardware Unit, Industrial Cameras, Computer System.

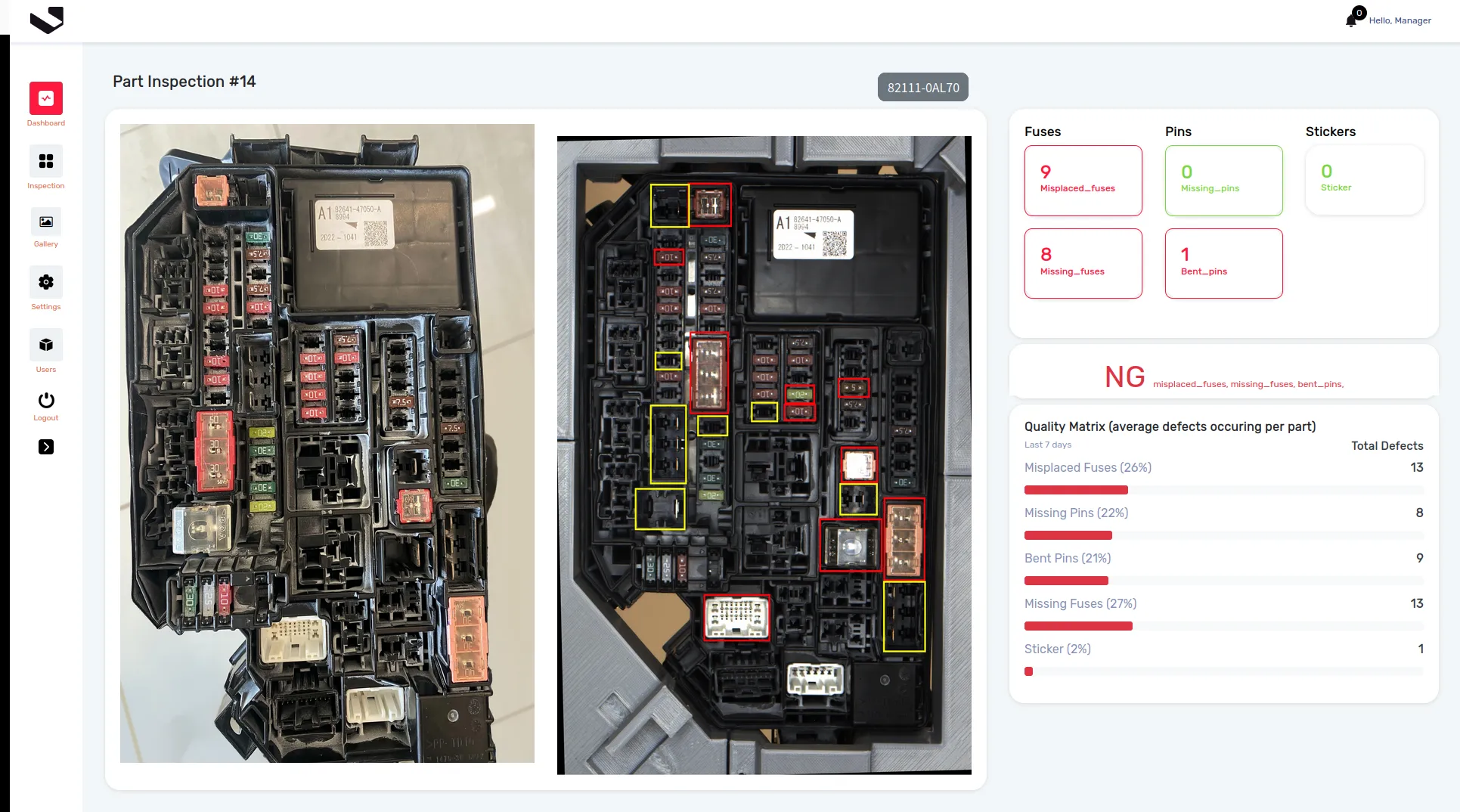

QC Dashboard

QC dashboard is deployed at the end of line inspection. It helps workers see the quality issues in cars so they can fix them in real-time.

Executive Dashboard

The executive dashboard is for the top management. It helps understand the quality issues in car manufacturing in depth. Understand why defects are increasing and help companies make data-driven decisions to reach SixSigma.

Maximize accuracy and minimize human error

Our system can also track and analyze data to identify patterns and trends, helping you to improve your

manufacturing process and prevent future defects.

Frequently Asked questions

Do you provide only the software or this is a full solution?

We provide full solution including hardware, softtware and full deployment.

Is this technology trusted for production use at factory?

This technology is trusted and already in production for Toyota Parts in factories.

Do I get a free trial for my factory?

Yes, you will get a free trial for your factory. We don't charge until you are satisfied